Bacteria, viruses and enzymes are inseparable part of food, milk, chemical and other many processing industries. However, the struggle has always been to protect from them, there could be plethora of reasons why these bacteria, viruses and enzymes needs to be killed/eliminated either for increasing the life, avoiding contamination, stop viral infection and many more. This process is very commonly known as sterilization. Sterilization can be attained by the multiple ways such as heating, irradiation, and filtration and by the way of chemical reactions, amongst all the sterilization processes the heat processing is one of the oldest and proven support processing system.

With advancement of technology and processing systems, the sterilization process has become more efficient and cost effective. There are many other processes across various industries that which we some time get puzzled with such as disinfection, sanitization, pasteurization and etc, but these processes are completely different from the sterilization, though, the basic purpose is to kill the contaminating bacteria and viruses.

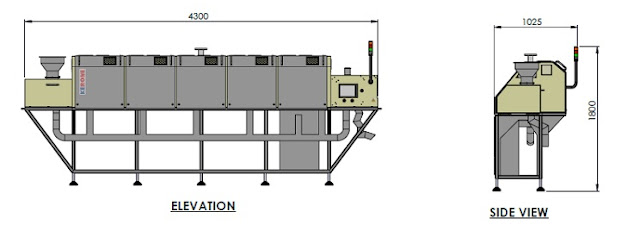

Heating systems based on advanced technology such as microwave, IR, Radio frequency and hybrid one have showcased very effective results. Now with the new AI and ML based systems can perform both sterilization and drying together unlike old systems where multiple staging was required to achieve the same.

Industries such as medical, pharmaceutical and food are having sterilization as one of their vital process for various applications. Industries those are having sterilization as critical process are:

- Medical and Surgical

- Pharmaceutical

- Chemical

- Laboratories

- Space crafts

- Food

- Microbiology and etc.

As I mentioned, sterilization by means of heating is there from ages buts the temperature needs to be risen to a point and kept for specified duration, deflection in any of both might result in not killing all viruses and bacteria or harming/changing the property of material under processing. Heating is very effective way of processing however how to heat is also important, there are flaming and non-flaming heating systems based on suitability of material under processing. Some heat sensitive materials need very precise control on temperature and duration.

Flaming heating is oldest type of the heating, same direct flame of the fire is used to sterilize the subjected material, whereas the other non-flaming heating of sterilization uses the hot air or hot water heating system. The new addition to list has been EM based heaters such as Microwave, IR and RF.

The flame based sterilization was not suitable for the all type of substrates hence the non-flame based heater (dry heat) is started getting popularity, in non-flaming biological agents are killed or made inactive by hot air, since the hot air are not direct heating type hence it does not have that much effectiveness, the electromagnetic based heating systems such as Infrared based haters, Microwave heater and RF heaters has proven their capability both in terms of raising the temperature quickly to deactivate/kill biological agents and suitability to the subject material.

Controlling of heat, time and flow of material is key success criteria for sterilization processing not this but in all heat treatment processing, hence at Kerone we utilize of more than 4 decades’ know-how of heat processing and combining it with the new age AI technologies to achieve better and faster results for type of processing needs. You can reach out to us for any query and enquiries write to us info@kerone.com

Comments

Post a Comment