Sterilization can be accomplished by an amalgamation of heat, chemicals, irradiation, high pressure and filtration such as steam under pressure, dry heat, ultraviolet radiation, gas vapour sterilants, chlorine dioxide gas etc. Successful sterilization strategies are necessary for working in a lab and negligence of this could lead to severe consequences, it could unexpectedly cost a life.

So what are the more frequently utilized methods of sterilization in the laboratory, and how do they work?

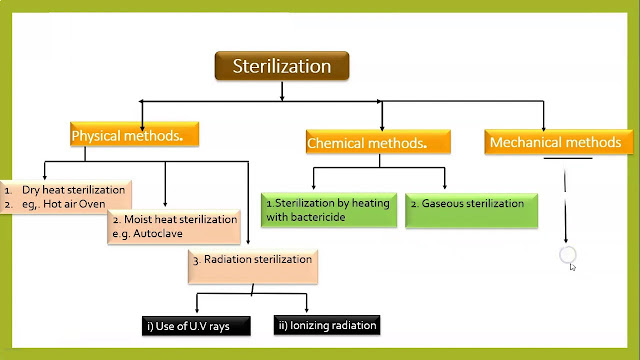

The Sterilization is conveyed out by the methods according to requirement. The methods are: 1. Moist Heat Sterilization 2. Dry Heat Sterilization 3. Gas Sterilization and Others.

- Moist Heat Sterilization: Moderate pressure is utilized in steam sterilization. Steam is utilized under pressure as a means of accomplishing an elevated temperature. It is dominant to confirm the accurate quality of steam is utilized in order to keep away the problems which follow, superheating of the steam, failure of steam penetration into porous loads, incorrect removal of air, etc.

- Dry Heat Sterilization: Dry heat sterilization is utilized for heat-stable non-aqueous preparations, powders and definite impregnated dressings. It may also be utilized for sterilization of some types of container. Sterilization by dry heat is generally carried out in a hot-air oven. Heat is carried from its source to load by radiation, convention and to a small extent by conduction.

This process can eliminate heat-resistant endotoxin. In each cycle it is predominant to make sure that the entire content of each container is maintained for a successful blend of time and temperature for most part to allow temperature variations in hot-air ovens, which may be considerable. Dry heat is utilized to sterilize glassware, porcelain and metal equipment, oils and fats and powders i.e. talc, etc.

- Gas Sterilization: Gaseous sterilizing agents are of two main types, oxidizing and alkylating agents. Vapour phase hydrogen peroxide is an example of the former. Ethylene oxide and formaldehyde are instance of the alkylating agents. However, the BP states that gaseous sterilization is used when there is no acceptable replacement. The main advantage of ethylene oxide is that many types of materials, including thermo labile materials, can be sterilized without damage.

Low temperature steam with formaldehyde has been utilized as an option for sterilizing thermo labile substances. Both ethylene oxide and formaldehyde have health risks and strict monitoring of personnel revealed to the gases required to make sure protection from harmful effects.

- Sterilization by Radiation: Radiations can be split up into two groups: electromagnetic waves and streams of particulate matter. The former group consists infrared radiation, ultraviolet light, X-rays and gamma rays. The latter group includes alpha and beta radiations. More frequently infrared radiation, ultraviolet light, gamma radiation and high-velocity electrons are utilized for sterilization.

(i) Ultraviolet Light:

A narrow range of UV wavelength is successful in eliminating the microorganism. The wavelength is powerfully absorbed by the nucleoproteins. The most important disadvantage of UV radiation as a sterilizing agent is its poor penetrating power. This is the result of powerful absorption by many substances. The application of UV radiation is limited.

(ii) Ionizing Radiations:

Ionizing radiations are satisfactory for commercial sterilization processes. It must have good penetrating power, high sterilizing efficiency, little or no damage result on irradiated materials and are capable of being produced efficiently. The radiations that satisfy these four measures are best high-speed electrons from machines and gamma rays from radioactive isotopes.

- Sterilization by Filtration: Membrane filters are built from cellulose derives or other polymers. There are no loose fibres or molecules in membrane filters. They keep molecules bigger than the pore size on the filter surface hence filters particularly useful in noticing of small numbers of bacteria.

Passage through a filter of suitable pore size can remove bacteria and moulds. Viruses and mycoplasma may not be maintained. After filtration the liquid is aseptically dispensed into formerly sterilized containers which are later sealed.

Other than this, it is tough to make universal statements about the various methods of sterilization because there can be huge non-identical in these considerations depending on the size and location of the sterilizer, as well as the methods waged for product release. All of these circumstances will influence selection of the sterilization process and the coherence with which it controls.

We at KERONE have a team of experts to help you with your need for Sterilization Machines from our wide experience. For any query write us at info@kerone.com or visit www.kerone.com.

Comments

Post a Comment