Many divergent heating and drying processes are needed during the manufacture and processing of textiles. High value, technical textiles must be fixed dependably and partially, coatings on fabrics and materials need to be dried as quickly as possible. The insistence on heating systems is continuously increasing and heating processes must keep pace with manufacturing processes. Infrared is a proven source of heat in textile processing, as infrared sends high heating power in extremely compact times. This helps to lessen energy consumption, to expand production speeds and to lower production costs.

Fibres and yarns are dyed, carpets are coated on their reverse side, curtains or blinds are printed – and infrared technology is perpetually there to help ensure that the required heating process is carried out quickly and beneficially. There is a broad spectrum of wavelengths, shapes and power products to choose from, the heating can be perfectly matched to product and process. That saves on time, effort and operating costs!

Heating periods should not compress the manufacturing process. Infrared heating technology helps to modernise production and improve quality. Infrared emitters ensure that car seat covers are crease-free, that interior carpets fit perfectly – and that airbags deploy expeditiously in an emergency. It pays to think infrared when we’re talking about cars.

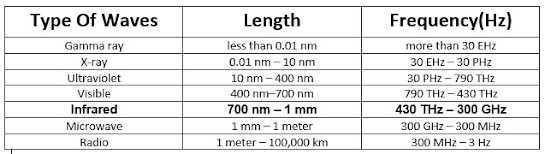

Infrared radiation (IR), is an electromagnetic wave with longer wavelengths than the visible light, thus it is invisible to the human eye.

Infrared heat fetching is eccentric compared to convection and conduction since the heat transmition is considered to be a heat source which propagates large quantities of heat energy to the fibres in a short amount of time. The infrared process is an environmental technique that lessens pollution by decreasing the waste dyes and electrolytes in the effluent from reactive dyeing, because of the high fixation that occurred using the infrared heating technique side by side to other conventional dyeing techniques.Infrared waves are contemplated to be in the lower-middle range of wave frequencies that is between microwaves and visible light. Infrared waves with longer frequencies generate heat such as fire, the sun and other heat producing sources. On the other hand, infrared waves with stubby frequencies do not produce high heat so, they are used in other technologies such as remote controls.

Drying is necessary to eliminate or reduce the water content of the fibres, yarns and fabrics following wet processes. Drying, in particular by water evaporation, is a high-energy-engrossing step.

Drying can be drawn on to the subsequent textile materials:

- Loose fibre

- Hanks

- Yarn Packages

- Fabric

Loose fibre drying:

The water content of the fibre is initially turned down by either centrifugal extraction or by mangling before evaporative drying.

Hanks drying:

Evaporative dryers contains a number of heated chambers with fan assisted air circulation, through which the hanks pass suspended on hangers or poles or supported on a conveyer. The hank sizes employed in carpet yarn processing require a slow passage through the dryer to ensure even final moisture content, and a residence time of up to 4 hours is not uncommon. Air temperature is maintained below 120°C to prevent yellowing.

Less commonly, hanks may be dried by employing a dehumidifying chamber. Moisture is recovered by condensation, using conventional dehumidification equipment. In comparison to evaporative dryers, yarn residence time tends to be longer, but energy utilization is lower.

Yarn packages drying:

The moisture of dyed packages is reduced at first by centrifugal extraction. Specially designed centrifuges, compatible with the design of the dyeing vessel and yarn carriers are engaged. Traditionally packages were oven dried, very long residence times being required to ensure sufficient drying of the yarn on the inside of the package. Two techniques are currently used, rapid (forced) air drying and radio frequency drying, the latter sometimes being cobined with initial vacuum extraction.

Fabric drying:

The fabric transported within two blankets through a set of drying modules. Internally each module the fabric is dried by means of a hot air flow. This apparatus is normally used for merged finishing operations on knitted and woven fabrics when, along with drying, a shrinking effect is also essential in order to give the fabric a soft hand and good dimensional firmness.

We at Kerone have 44+ years’ experience in infrared heating technology and provide individual advice and service. Kerone offers its customers the potential for proving trials in its in-house Applications Centre or on-site with experienced technical assistance.

For any query write us at info@kerone.com or visit www.kerone.com.

Comments

Post a Comment