Nanotechnology is impacting the sector of goods, many merchandise that incorporate nanomaterials are already in a variety of items; several of which individuals don’t even understand contain nanoparticles, merchandise with novel functions starting from easy-to-clean to scratch-resistant. Samples of that automobile bumper are created lighter, clothing is a lot of stain repellent, Sunscreen is more radiation resistant, synthetic bones are stronger, cell phone screens are lighter weight, glass packaging for drinks results in an extended shelf-life, and balls for varied sports are created a lot of sturdy. Exploitation nanotech, within the mid-term trendy textiles can become “smart”, through embedded “wearable electronics”, such novel merchandise have conjointly a promising potential particularly within the field of cosmetics, and has various potential applications in significant trade. Technology is foreseen to be a main driver of technology and business during this century and holds the promise of upper performance materials, intelligent systems and new production ways with important impact for all aspects of society.

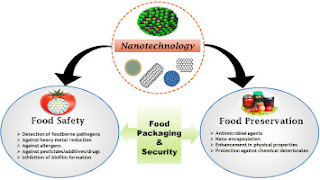

A complex set of engineering and scientific challenges within the food and bioprocessing industry for producing prime quality and safe food through economical and property suggests that is solved through Nano technology. Bacterium identification and food quality watching victimization biosensors; intelligent, active, and sensible food packaging systems; Nano encapsulation of bioactive food compounds are few samples of rising applications of Nano technology for the food trade. Nano technology is applied within the production, processing, safety and packaging of food. A Nano composite coating method might improve food packaging by putting anti-microbial agents directly on the surface of the coated film. Nano composites might increase or decrease gas permeableness of various fillers as is required for various merchandise. They will conjointly improve the mechanical and heat-resistance properties and lower the gas transmission rate. Analysis is being performed to use engineering science to the detection of chemical and biological substances for sensanges in foods.

In general, food substances don’t seem to be allowed to be adulterated. New foods area unit among the nanotechnology-created client merchandise returning onto the market at the rate of three to four per week. A whole of canola vegetable oil referred to as Canola Active Oil, a tea called a Nano tea and a chocolate diet shake referred to as Nanoceuticals Slim Shake Chocolate. According to step with data, the oil contains associate additive referred to as “Nano drops” designed to hold vitamins, minerals and phytochemicals through the digestive system and Urea.

Some of the packaging steps are mentioned below:

- Food Packaging

- Barrier Protection

- Antimicrobial Protection

- Bio – Degradable

- Smart Packaging

Nutritional supplements with the combination of Nano technology deliver the drugs with efficiency. Also several industrial nutraceuticles square measure on the market. These supplements move most powerfully with cells and simply acceptable. Even supposing Nano Technology came to result in foods by producers’ it’s however to be recognized by the customers, because of the moral problems and unawareness. The potential use of Nano technology and its edges in business and customer’s health needs to be unfold. Prospective analysis in Nano technology in food business and its incorporation have the potential to reinvent food world. Likewise certain laws have to be compelled to be created by the food administration department of the countries government to determine correct and safe commercialisation of Nano food. The interaction of nanoparticles and cells ends up in debate regarding some pessimistic approach to Nano foods .But the wide potential of Nano technology in overall food business and its edges in providing wealthy organic process worth, quality packaging, sensible sensing square measure to be borne in mind and relevant analysis for additional safer techniques for incorporation of Nano technology in food industry needs to be implemented.

We at KERONE have a team of experts to help you with your need for Nanotechnology in various products range from our wide experience. For any query write us at info@kerone.com or visit www.kerone.com.

Comments

Post a Comment